|

|

| Line 66: |

Line 66: |

| | |lines=10 | | |lines=10 |

| | |footer= | | |footer= |

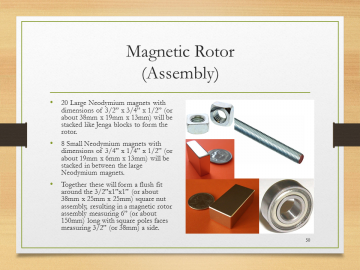

| − | |Let's Build the S.H.O. Drive! - Slide 044 of 176.png||'''In Phase 2…'''<br>• First on the list is to assemble a rotor of neodymium magnets onto the shaft.<br>• Second on the list is to insert the rotor through the bearings securely into the disassembled wooden panels.<br>• And third is to reattach the wood panels back onto the wood base blocks. | + | |Let's Build the S.H.O. Drive! - Slide 044 of 176.png||'''In Phase 2'''''<br>• First on the list is to assemble a rotor of neodymium magnets onto the shaft.<br>• Second on the list is to insert the rotor through the bearings securely into the disassembled wooden panels.<br>• And third is to reattach the wood panels back onto the wood base blocks. |

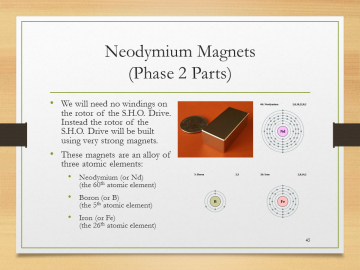

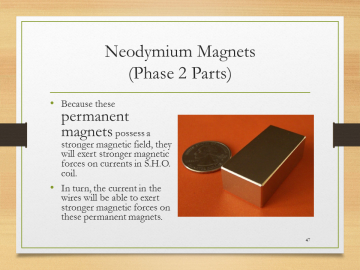

| | |Let's Build the S.H.O. Drive! - Slide 045 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• We will need no windings on the rotor of the S.H.O. Drive. Instead the rotor of the S.H.O. Drive will be built using very strong magnets.<br>• These magnets are an alloy of three atomic elements:<br>• Neodymium (or Nd)'''<br>''(the 60th atomic element)''<br>• Boron (or B)'''<br>''(the 5th atomic element)''<br>• Iron (or Fe)'''<br>''(the 26th atomic element) | | |Let's Build the S.H.O. Drive! - Slide 045 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• We will need no windings on the rotor of the S.H.O. Drive. Instead the rotor of the S.H.O. Drive will be built using very strong magnets.<br>• These magnets are an alloy of three atomic elements:<br>• Neodymium (or Nd)'''<br>''(the 60th atomic element)''<br>• Boron (or B)'''<br>''(the 5th atomic element)''<br>• Iron (or Fe)'''<br>''(the 26th atomic element) |

| | |Let's Build the S.H.O. Drive! - Slide 046 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• These Neodymium magnets are from Magnet4less.com and are pound-for-pound some of the strongest permanent magnets that you yourself can buy on the market today.<br>• These are often used in making wind turbine generators. | | |Let's Build the S.H.O. Drive! - Slide 046 of 176.png||'''Neodymium Magnets'''<br>''(Phase 2 Parts)''<br>• These Neodymium magnets are from Magnet4less.com and are pound-for-pound some of the strongest permanent magnets that you yourself can buy on the market today.<br>• These are often used in making wind turbine generators. |